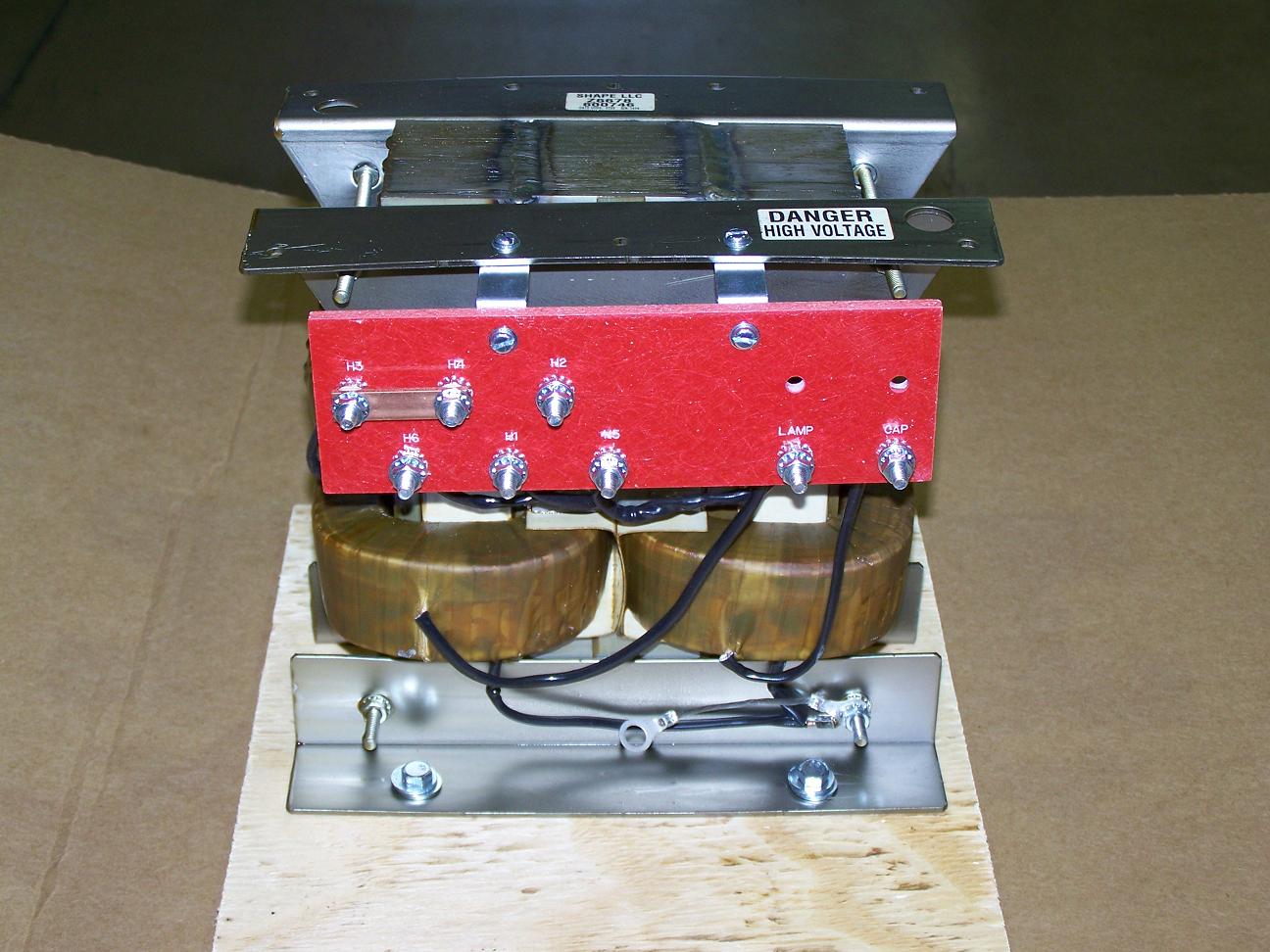

TRANSFORMERS-HIGH POWER REGULATING BALLASTS

Infralight supplies a range of specialty transformers for many applications including UV curing, print curing and the water disinfection industry. Infralight transformers are specifically made for medium pressure discharge lamps. Designed to operate medium pressure ultraviolet lamps, these transformers need to be extremely efficient at regulating current.

- Electronic controlled ferroresonant

- Constant voltage

- High powered regulating ballasts for UV lamps

- Isolation Transformers

- Power transformers

The following are several reasons we believe you’ll want to use Infralight’s electronically controlled ferroresonant ballasts and constant current regulators.

- Lower Operating Costs

High spectral efficiency results in greater UV output/watt input for a more efficient curing process. - Cure Heat-Sensitive Substrates

Reduced infrared emissions and cooler temperature around the UV lamp provides a safer environment for heat-sensitive substrates. - Improved Quality and Efficient Curing

Continuously variable output power maintains lamp intensity, and unreliable mercury relays can be eliminated. In addition, output power can be set manually, or controlled with PLC. Once the output power is set, it will maintain constant power to the lamp within 2% of the target value over the entire input voltage range. - Lamp Interchangeability

Mercury vapor, or metal halide, lamps can be used interchangeably with our CFB’s. - Quicker Equipment Startup

Infralight’s controlled ferroresonant transformers provide the fastest warm-up available. - Designed to Last

Our CFB’s are designed so short circuits will not damage your system, resulting in longer life.

Controlled Ferroresonant Ballasts (CFB) are PLC-controllable and have analog outputs to provide feedback on system status (i.e. lamp voltage; lamp current; and warm-up, ready, or fail modes.)